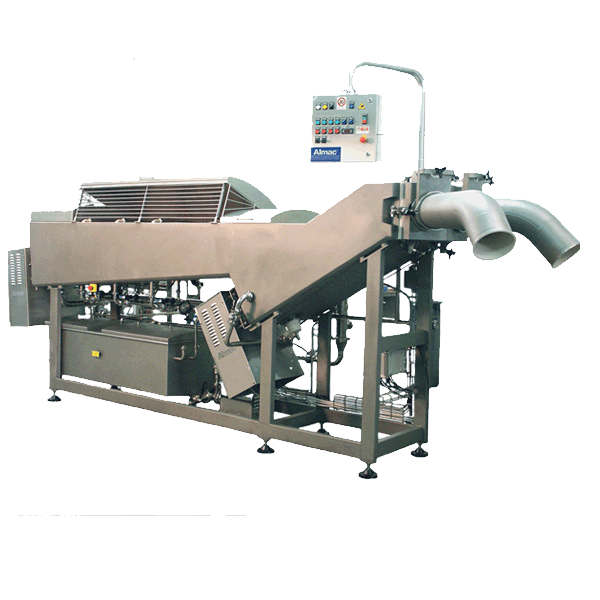

FC 3000

Hourly output up to 2000 kg

The stretcher mod. FC 3000 is a machine designed for the continuous production of pasta filata starting from minced curd at the right acidity degree.

Suitably acidified curd is cut and transferred to the cooking chamber equipped with the first pair of augers. In this area, curd comes in contact with the hot water and the combined action of acidity and temperature modify the row material structure, thus assuming the typical fibrous aspect.

Augers are lightly inclined so that the curd, at the beginning, comes in contact with a bigger water quantity for a more uniform heating action.

This mixture is then transported towards the second section, where other two augers, by their mechanical action, push pasta towards an extruding outlet. The combined action of the pushing and the counter-pressure increases the product natural structure. When water reaches the desired temperature, it is distributed on the curd by a tube and the flow is adjusted by butterfly valves. Water level is controlled by an adjustable overflow pipe. After having transferred the heat to the curd, water is filtered by two perforated plates located on the cooking section walls. Then, water returns to the lower vat and it is eventually circulated again or replaced according to the applied technology.

Construction features

The steam stretcher mod. FC 3000 is composed by:

- The machine is completely built in AISI 304 stainless steel and plastics certified for the food use.

- Parts in contact with the cheese are coated by non-sticking material.

- Mixing chamber composed by rounded plates and dismountable filter for the stretching water discharge.

- Air-filled double jacket around the augers section to allow the thermal insulation from the external environment.

- Dismountable stretching water discharging filter.

- Dough feeding augers built to be easily dismounted without using any tool.

- Dough adjustable transport speed by inverter according to the desired cheese.

- Motorization equipped with spacer to allow the cleaning between the motor and the stretching chamber.

- Stretching water preparation vat heated by direct steam injection, managed by ad electrovalve controlled by an electronic thermoregulator equipped on the control panel.

- Safety filter able to accumulate all machine discharge, easy to be inspected and sanitized.

- Stretching water level probe.

- Connections with bending radius built in such a way to avoid any stagnation point.

- Electropump for the stretching water circulation.

- Stretching water evacuation electropump.

- Stretching water thermoregulation.

- PT 100 probe for the stretching water temperature detection.

- Motorizations protected by AISI 304 stainless steel cases.

- Watertight electrical control panel with IP 65 protection degree, built in AISI 304 stainless steel, complete with electronic devices for the processing speed adjusting and the operator’s safety control.

- Motorizations with watertight oil-bath speed variator, complete with case that allows, in case of oil leakage, the discharge to the ground thus avoiding any cheese pollution.

- Motorization equipped with spacer for allowing the cleaning between the motor and the stretching section.

- Inverters and electrical motors group for the two augers sets with direct control from the panel. Control board for the inverters group assembling.

- Stainless steel working catwalk of the same machine length.

- Dismantling easiness of the movable parts without using any tool and complete inspection possibility.

- Set of safety sensors against accidents to start the machine stop up in case of guards opening

Advantages

The advantages that can be obtained by means of the stretching machine mod. FC 3000 can be resumed as follows:

- The machine offers to the operator the possibility to adjust the following parameters:

- COOKING SECTION

- water temperature

- water level

- augers speed and consequent curd heating time (a suitable combination of the above mentioned parameters allows the final cheese moisture to be affected).

- STRETCHING SECTION

- augers speed

- counter-pressure on the pasta filata flow for the extruding mouth opening adjusting (a suitable combination of the above mentioned parameters allows the final cheese moisture to be affected).

- COOKING SECTION

- The cooking section volume and the augers dimension allow to the operator the working technology requested temperature to be obtained without using too high “delta T” that may cause an excessive breaking of the caseous structure during the physical transformation process, with consequent big fat and proteins losses. In fact, the big working area allows reaching the same thermal exchange using water at a lower temperature and in a longer time; this, in addition to reduce the losses, positively affects also product quality. Stretching section, thanks to the extrusion action application, helps to obtain a compact product with well distributed moisture, key condition to obtain a long product shelf-life.

- Stretching water temperature uniformity, assured by the thermoregulator equipped on the control panel and by the air-filled double jacket which provides the augers chamber external thermal stabilization.

Optional

Automatic C.I.P. washing plant connection arrangements

Technical data

Stretcher mod. FC 3000

- Height (mm) 1950

- Width (mm) 775

- Discharging height (mm) 1290

- Weight (empty machine) (Kg) 1800

- Hourly production (Kg/h) 2500-3000

- Horizontal augers length (mm) 2.000

- Augers diameter (mm) 300

- Inclined augers length (mm) 1.100

- Augers diameter (mm) 300

- Frequency (Hz) 50

- Installed electrical power (kW) 5,2

- Absorbed current (A)