FS 100/N

Hourly output up to 1000 kg

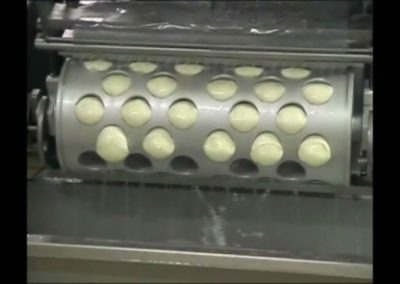

The moulding machine mod. FS 100/N is designed for production of pasta-filata cheeses with high moisture content, such as:

MOZZARELLE – FIOR DI LATTE – SCAMORZE – PROVOLE – PLAIT CHEESES – NODINI

having variable weights from 0.5 gr. to 500 gr. and up to 1200 gr by using a special moulding drum.

The machine can be fed either directly by a continuous cooker- stretcher or by other types of discontinuous mixing machines. Pasta filata is introduced into the hopper and by means of four counter-rotating screws it’s transported to the moulding drum. The augers chamber is surrounded by a double jacked, heated by heating elements to keep pasta temperature constant.

Construction features

- Machine completely built in AISI 304 stainless steel and plastic materials certified for the food use.

- Parts in contact with the cheese are coated with non-sticking material.

- The augers chamber is equipped with water double jacket, heated by an electrical heating element.

- Dismountable stretching water discharging filter.

- Dough feeding augers built to be easily dismantled without using any tool.

- Adjustable moulding drum and augers rotation speed.

- Motorizations protected by AISI 304 stainless steel cases.

- Motorization equipped with spacer to allow the cleaning between the motor and the moulding chamber.

- Augers and drum motorizations with watertight oil-bath speed variator, complete with case that allows, in case of oil leakage, the discharge to the ground thus avoiding any cheese pollution.

- Connections with bending radius built in such a way to avoid any stagnation point.

- PT100 probe for detecting the water temperature into the double jacket

- Watertight electrical control panel with IP 65 protection degree, built in AISI 304 stainless steel, complete with electronic devices for the processing speed adjusting and the operator’s safety control.

- Dismantling easiness of the movable parts without using any tool and complete inspection possibility.

- Set of safety sensors against accidents to start the machine stop up in case of guards opening

Advantages

- Possibility to mould a cheese with very high moisture content, keeping the cheese skin natural brightness and ensuring a good sealing on the cutting point.

- Possibility to change, through a 2-positions adjustment, the machine inclination.

- Possibility to mould also small quantities of cheese with the quick replacement of the drums.

- Pushing made by the augers on the pasta surface is always constant and delicate, thus allowing the machine FS 100/N to be suitable both for the cow’s milk and the buffalo’s milk mozzarella production.

- Simple controls with the possibility to check the processed quantities by means of a pieces-counter.

- Easy disassembly by the operator of parts in contact with foodstuffs without the help of any tool for facilitating the washing and sanitation operations.

Technical data

Moulder mod. FS100/N

- Length (mm) 1155

- Height (mm) 1800

- Width (mm) 1420

- Feeding height (mm) 1220

- Discharging height (mm) 690

- Augers diameter (mm) 150

- Weight (empty machine) (Kg) 200

- Hourly production (Kg/h) 150 -1500

- Line tension (V) 400

- Auxiliary circuits tension (V) 24

- Frequency (Hz) 50

- Installed electrical power (kW) 2.7

- Absorbed current (A) 6.75